What do chocolate and cement have in common? More than you might think.

Chocolate is made by mixing liquid and finely ground cacao beans in a device that bears more than a passing resemblance to a cement mixer. In both cases, stirring tiny granules in a fluid results in a substance with very specific properties — for chocolate, it’s a meltingly smooth mouthfeel, and for cement, it’s a cohesive, consistent texture.

However, while physicists have studied the physics of cement mixing, fewer have taken a close look at the forces at work in chocolate conching, as the process is called. Now a team of physicists, funded in part by Mars, the confectionary company, published a paper last week in the Proceedings of the National Academy of Sciences showing just what happens as the ingredients of chocolate are given a stir on their way to becoming a delicious treat.

[Like the Science Times page on Facebook. | Sign up for the Science Times newsletter.]

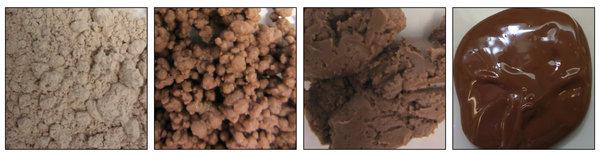

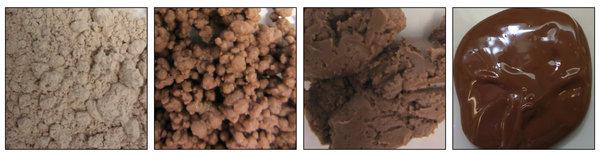

When conching was invented in 1879 by Rodolphe Lindt, it could take more than a day of steady mixing for gritty chocolate to grow smooth. Today, it is a shorter process. For this study, the researchers spun cacao powder and a bit of oil in a conching machine for 40 minutes. They took photographs as the stuff went around, then added more oil during the final phase, which lasted an additional 20 minutes.

CreditElena Blanco and Daniel Hodgson

What they saw was that much like what happens in a cement mixer, the dry paste formed from the powder and the fluid made shaggy clumps. Then, at a certain point, it morphed into a more liquid-like state and started to flow. Adding the extra oil near the end just encouraged the process, resulting in a shining creamy liquid straight out of Willy Wonka’s chocolate waterfall.

What’s happening here? The researchers suggest that as the granules of powder bump up against the stirrer, the fluid and each other, the level of friction they experience at first rises. They then stick together into larger wads or aggregates. Given enough time, the aggregates start to roll past each other more easily. That may result from being worn smooth, or at least compacted, by all the bumping around, said Wilson Poon, a professor of physics at the University of Edinburgh who led the study.

He speculated that, “They get less angular, less rough.”

As the conching continues, adding extra oil further reduces the friction between the aggregates, allowing the whole mixture to flow.

Understanding the underlying physics may help chocolatiers decide just how long and at what speed to conch chocolate, and when to add the right amounts of ingredients. It could lead to greater efficiency, said Dr. Poon.

“Conching is one of the more energy expensive steps of chocolate making,” he said. “We think that once you understand the actual process, it may well be possible to reduce the amount of energy used.”

The particular chocolate made in this study, alas, went untasted. “We don’t have a food grade lab,” said Daniel Hodgson, a researcher also at the University of Edinburgh and one of the co-authors, “so any samples prepared in our labs are only for experimentation.”